Metal Roofing in Central, TX

A professionally installed metal roof is a smart investment that adds long-term value, efficiency, and protection to your home. Residential metal roofs are available in a variety of styles and colors. Our metal roofing systems combine durability, curb appeal, and eco-friendly performance built to withstand even harsh Texas weather.

Spade Roofing and Gutters offers a 5-year workmanship warranty on all roof replacements.

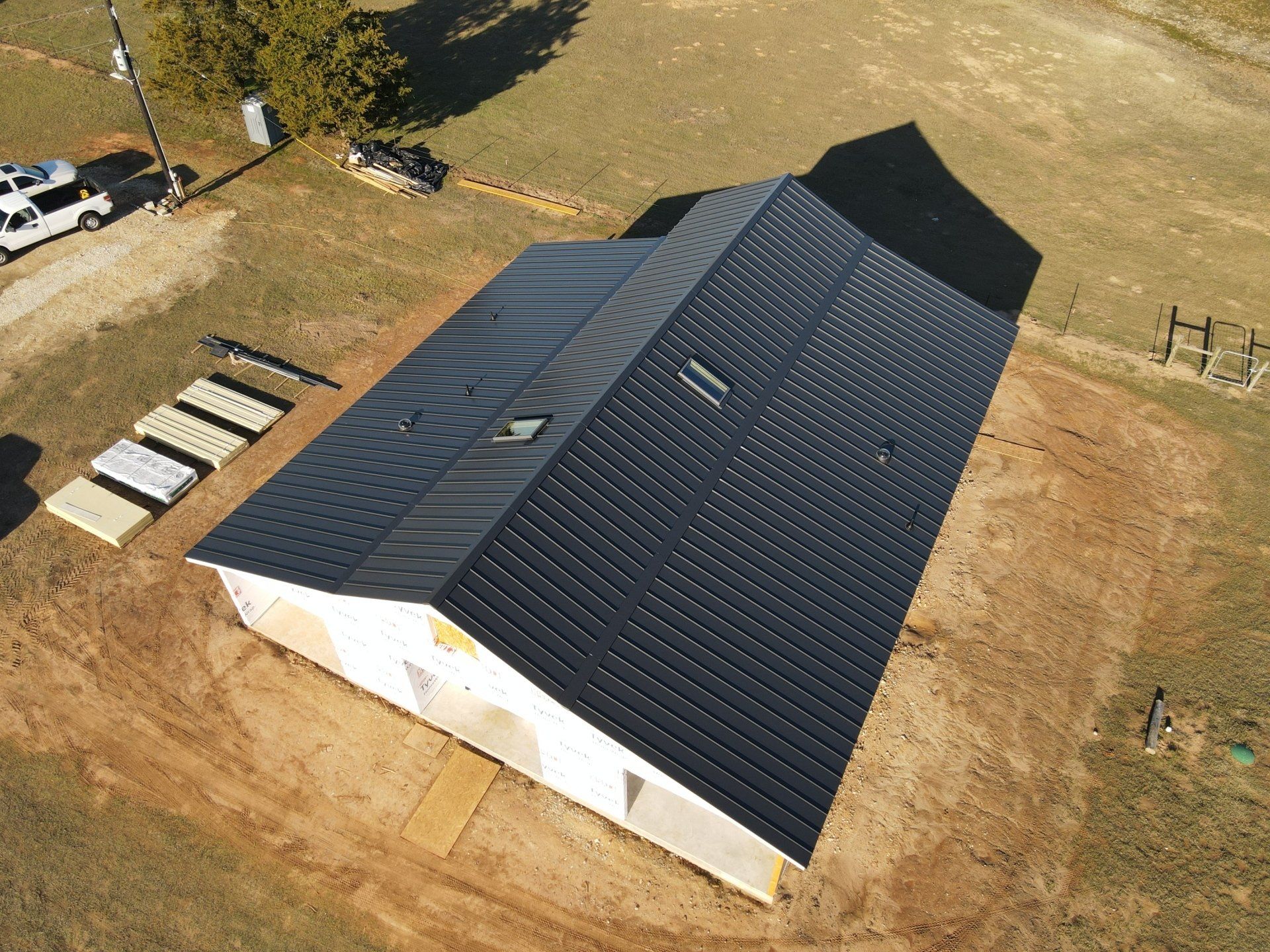

Standing Seam (Concealed Fastener) Metal Roofing Systems

A standing seam (concealed fastener) metal roof utilizes a concealed fastener system which uses fasteners that are hidden offering a smoother, sleeker appearance and reduce the risks of leaks by having fasteners that are not exposed to the elements over time. Our standing seam (concealed fastener) metal roofing system is custom fabricated to precisely fit your home, ensuring optimal protection, clean aesthetics, and long-term performance and durability.

Key Features:

- Hidden Fasteners: The fasteners are concealed beneath the seams, protecting them from weather exposure and reducing the risks of leaks.

- Durability: Made from high quality steel or aluminum, panels are performance tested for wind, hail, and fire.

- Clean, Modern Look

- Low Maintenance: With fewer exposed parts and tight interlocking seams, it requires less upkeep.

- Energy Efficient: Often coated with reflective paint systems that reduce solar heat gain and lower cooling costs.

- Long-Lasting

- Allows for Thermal Movement

- Great Investment and Enhanced Curb-Appeal

Exposed Fastener Metal Roofing Systems

Exposed fastener metal roofing is a cost-effective metal roofing system where the screws (fasteners) that secure the panels to the roof decking or structure are visible on the surface of the roof. Each fastener goes through the metal panel and directly into the roof structure, holding the panels in place. The screws have a rubber washer at the base to help seal out water, but over time, these washer can degrade, and the screws can loosen due to the natural expansion and contraction of the metal.

Key Features:

- Cost-Effective: Generally more budget-friendly.

- Visible Screws: You can see the screws. The screws are sealed with a washer to help prevent leaks.

- More Industrial and Traditional Appearance: The visible screws don't diminish their aesthetic appeal but do give a more industrial and traditional feel.

- Quicker Installation: These panels are fastened directly through the panel and into the roof deck or frame using screws.

- Can Require More Maintenance or Upkeep: Unlike concealed fastener panels, the screws on exposed fastener panels are exposed to the elements and will experience more wear and tear. Eventually, it will be required to tighten or replace the screws and washers to ensure the integrity of the roof.